Bridging engineering and creativity, the hidden power of integrated product design

For decades, product development has often operated like a relay race. The baton of ‘Creativity’ is passed from design to engineering, and then to manufacturing. But these handoffs are where the true intent of a product often gets diluted. The result is products that may be perfectly functional but ultimately uninspired, or beautiful but prone to real-world failure. This linear, siloed model is no longer a sustainable approach to modern innovation.

Today, that linear approach no longer holds up.

We’ve seen the outcome of the old ‘hand-off’ model countless times: unnecessary cost, late-stage compromises and ultimately, a product that feels disconnected in the hands of the user. At Ticket Design, we reject this artificial separation. We know that real innovation, the kind that delivers truly exceptional medical devices, intuitive consumer electronics, and resilient industrial tools, is born not from isolated silos, but from a unified team. Integrated Product Design is our consultancy’s core philosophy. It’s the mindset shift that ensures engineering decisions elevate the user experience, design concepts are feasible from day one, and the final product feels coherent and intentional.

The false divide between engineering and creativity

There’s a persistent myth in product development: that creativity belongs to designers, while engineers are there to “make it work.”

In reality, both roles are deeply creative.

- Designers solve problems through form, interaction, and experience.

- Engineers solve problems through structure, systems, materials, and logic.

At Ticket Design, we staff our project teams with ‘T-shaped’ professionals who inherently bridge this gap: designers with a strong technical foundation and engineers with a deep appreciation for user experience.

When these perspectives operate in silos, friction is inevitable. Designers may push concepts that are difficult to manufacture. Engineers may optimise for feasibility at the expense of user delight. Both outcomes limit a product’s true potential.

Integrated product design challenges this divide by encouraging collaboration over handoffs and shared ownership over isolated responsibilities.

What does integrated product design really mean?

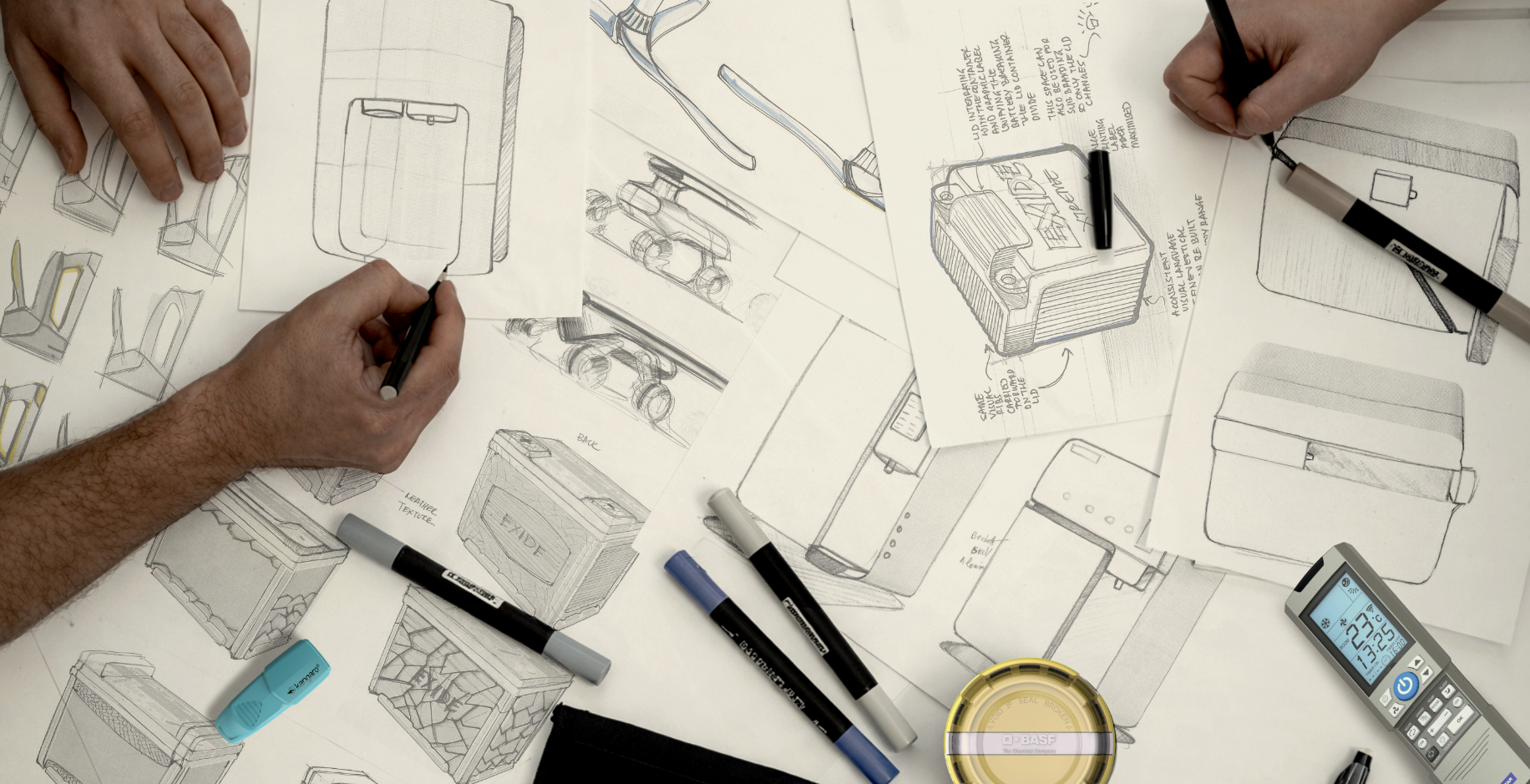

Integrated product design is not about adding more meetings or blending job titles. At its core, it means:

- Engineering and design collaborate from the earliest ideation stages

- Constraints are embraced early, not treated as obstacles later

- Decisions around form, function, materials, and manufacturing happen together

For a consulting firm, ’embracing constraints’ means bringing in manufacturing partners and cost models during the concept sketching phase, not just after CAD modelling is complete

Instead of asking, “Can we engineer this design?”, teams ask,

“How do design and engineering evolve together to solve this problem?”

This shift changes everything, from how ideas are generated to how products are realised.

Creativity becomes stronger with constraints

One of the most underestimated benefits of integration is how it strengthens creativity rather than limiting it.

When designers understand engineering constraints early, material behaviour, tolerances, cost implications, and assembly logic, they don’t become restricted. They become sharper. More intentional. More inventive.

Constraints act as creative catalysts:

- A material limitation can inspire a new form factor

- A manufacturing process can influence a smarter assembly

- An engineering insight can unlock a simpler user interaction

Creativity thrives not in the absence of limits, but in dialogue with them. We see this especially in projects with difficult sustainability goals, where material limitations force genuinely new and inventive solutions.

Engineering gains meaning through user context

The integration works both ways.

When engineers are brought into conversations about user behaviour, ergonomics, and experience goals, technical decisions gain context. Engineering choices are no longer just about performance metrics; they’re about real human use.

This leads to:

- Smarter component placement driven by usability

- Reduced over-engineering where it doesn’t add value

- Solutions that are robust and intuitive

Engineering becomes more purposeful when it’s grounded in how people actually interact with products.

Reducing rework, risk, and late-stage compromises

One of the clearest business advantages of integrated product design is efficiency.

In traditional workflows, disconnects often surface late:

- A design that looks great but can’t be tooled easily

- A component layout that clashes with the intended form

- A cost issue was discovered after extensive development

Our integrated process typically cuts the number of major design iteration cycles post-prototyping by 30-50%, translating directly to lower costs and faster time-to-market for our clients. Integration reduces these risks by surfacing challenges early, when they are easier and less expensive to solve.

The outcome is:

- Fewer redesign loops

- Faster development timelines

- More predictable production outcomes

Instead of firefighting problems at the end, teams make smarter decisions throughout.

From product to experience, A unified outcome

Users don’t experience design and engineering separately. They experience the product as a whole.

They notice:

- How it feels in the hand

- How intuitive it is to use

- How reliable does it feel over time

- How seamlessly form and function align

Integrated product design ensures that these experiences are intentional, not accidental.

When creativity and engineering inform each other continuously, the final product feels coherent. Nothing feels forced. Nothing feels like a compromise. Everything feels considered.

Collaboration as a design tool

Integration isn’t just about process; it’s about culture.

Teams that practice integrated product design tend to:

- Communicate more openly across disciplines

- Question assumptions earlier

- Make decisions with a shared understanding of goals

Sketches, prototypes, simulations, and models become shared tools rather than discipline-specific artefacts. Conversations shift from “my part” to “our product.”

For example, we use a hybrid physical/digital prototyping stage we call ‘Reality Checkpoints’ to ensure all teams are evaluating the product on the same shared artefact, not just their siloed documents

This collaborative mindset often becomes a competitive advantage, especially in complex or innovation-driven projects.

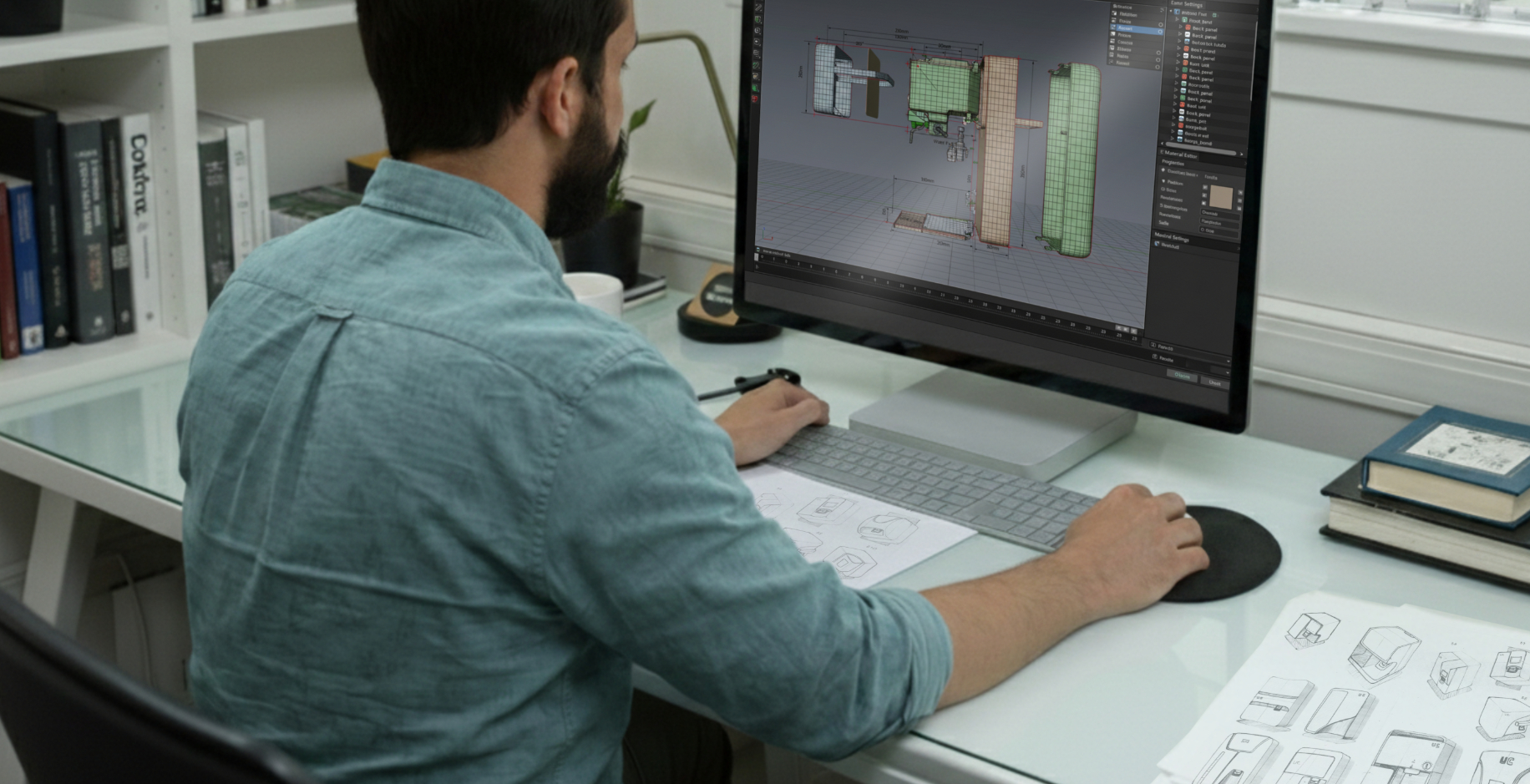

Our Approach: where design and engineering evolve together

In our experience, the most successful products are rarely the outcome of a perfectly executed handoff. They emerge when design and engineering grow in parallel, informing, questioning, and refining each other at every stage of development. Ticket Design’s approach to integrated product design is built around early collaboration. Engineers are involved from the first conversations around user needs and product intent, while designers remain closely engaged as technical decisions take shape. This overlap helps surface constraints early, align expectations, and avoid late-stage compromises that dilute the original vision.

For a recent medical device client, this early-stage involvement allowed us to re-engineer a complex sterilisation path from an expensive seven-step process to a simpler three-step process while still in the concept phase, saving significantly in manufacturing costs.

Why integrated design matters more than ever?

- Medical devices must be precise, intuitive, and compliant

- Consumer products must balance aesthetics, cost, and sustainability

- Industrial products must be robust yet user-friendly

Meeting these expectations requires more than excellence in individual disciplines. It requires alignment.

Integrated product design is no longer optional; it’s essential for creating products that are relevant, resilient, and ready for real-world impact.

Finally

At its heart, integrated product design is about respect, respect for different perspectives, different expertise, and the complexity of real-world problems.

When engineering and creativity come together early and often, products become more than the sum of their parts. They become thoughtful, functional, and meaningful solutions that stand the test of time.

The hidden power isn’t in choosing between logic and imagination; it’s in letting them work side by side.

If your product roadmap requires this level of thoughtful integration to achieve market relevance and true innovation

Contact to discuss how Ticket Design can partner with your team.